Aging/Hydrolysis of the PU rubber sole ➤ Reasons and background

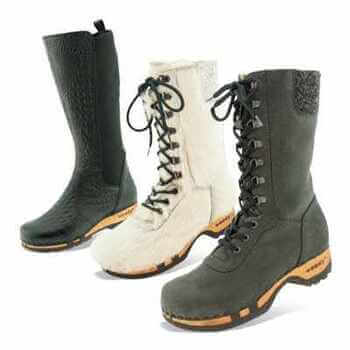

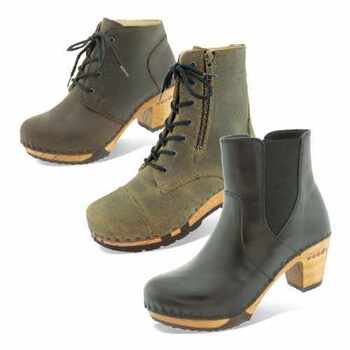

In the following article we will shed light on a phenomenon that occurs with some of our shoes and clogs with PU rubber soles: crumbling of the sole.

Here we answer the following questions:

- Why can the PU rubber sole come off/decompose?

- How long will my PU rubber sole last?

- Why do we use PU rubber soles in our shoes and clogs?

- What can I do to ensure that my sole lasts as long as possible?

- What can I do if my sole is already coming off?

Shoes are meant to be worn and so the sole is the part that is subjected to the most stress. Intensive use can cause wear and tear. For this reason, woody® offers resoling or sole replacement for all of our shoes with wooden soles. In addition to wear and tear on the treaded sole, there are also other reasons why the sole may need to be replaced. Cases in which the PU rubber sole of our shoes dissolves are particularly affected. Little or barely used, older shoes are particularly affected. With shoes that are used regularly, this problem occurs much less often or later.

We would like to explain to you what the diffusion of PU rubber soles is all about, what you should pay attention to and how we can help you if something happens.

Why can the PU rubber sole dissolve?

If the undersole of your shoes is peeling off the wood or crumbling, then this is most likely due to the aging process of PU plastic parts. Many beloved shoes have already fallen victim to this phenomenon. PU plastic is also used in mountaineering and hiking boots or running shoes. A closer look reveals that the topic is more complex than initially assumed. The deterioration process of the sole depends on many factors, the well-known hydrolysis being just one of these factors.

Reason #1: Hydrolysis

Hydrolysis describes the chemical deterioration process of polyurethane-based materials triggered by moisture. This causes the sole to lose its flexibility and ultimately the shoe loses its sole. The absolute humidity during storage is particularly relevant.

Reason #2: Bacterial infestation or chemicals and acids

Another factor is bacterial infestation or contact with acids, for example. Bacteria settle in the open-pored structure of the PU foam and attack the polymer structure. Contact with cow dung or salt water is often enough if it has not been washed off carefully over a long period of time.

Reason #3: Heat, UV radiation and ozone

Drying quickly or too hot increases the risk that the PU rubber will also be damaged. The material dries out and loses its elasticity. This also applies to high levels of UV radiation and ozone. This should be taken into account when choosing the drying location.

How long does a PU rubber sole last?

The time period in which the sole can loosen/crumble depends on many factors. Our experience shows that with regular use and proper maintenance, the earliest point at which a decomposition effect can occur is approximately five years after production. However, many customers only send their shoes for resoling after more than 6 or even up to 10 years. It is important that it is not the period of use, but the time since production. If you have problems with your shoes/soles within the first two years of purchase, please contact our service team with the purchase invoice. A repair is then still covered by our warranty.

Why does woody use PU rubber soles?

PU rubber soles provide constant cushioning over many years and are particularly dimensionally stable. They can withstand physical stress from rocks and branches, are light and flexible. These properties make PU rubber the preferred choice for our shoes and clogs. woody® uses the best PU rubber available and works closely with suppliers to continually improve sole technology.

Important tips to extend the life of your sole

Regular wear: Our experience shows that shoes that are worn regularly are less likely to lose their soles than shoes that remain unused for a long time. This is because the plasticizers in the sole remain supple and the chemical breakdown process is slowed down.

Storage: Ideally store your hiking boots in a dry, dark and well-ventilated room. Dryness refers to absolute humidity, including temperature, as warm air can store more moisture.

Care: If you have walked through fresh dung, manure or salt water, clean your shoes thoroughly. The acids in the manure and the salt water accelerate the hydrolysis process considerably. The same applies to earth, clay or moorland soils. You can find further care instructions here: Cleaning & Care .

Drying: Do not dry your shoes directly on or near a heat source such as a radiator or tiled stove. The heat can damage the sole material and the bonds in the shaft and cause the leather and PU rubber to dry out and crack. Also avoid exposing the shoes to direct sunlight or strong heat for long periods of time, as UV rays and heat can significantly affect the material's consistency. Heat in the trunk of a car is particularly harmful.

Visual inspection: In order to avoid unwanted detachment of the sole during tours, we recommend subjecting shoes that have not been worn for a long time to a thorough visual inspection. A short test tour after a long period of storage can prevent unpleasant surprises. Since aging processes also work from the inside out and are not always visible on the outside, a visual inspection and test tour is only of limited significance.

Resoling: In order to prevent problems during use, we recommend having PU soles resoled approx. 5-8 years after production.

Advice: If you need further information about the condition of your shoes, please contact our service team at woody@woody.co.at .

What to do if the sole breaks?

If the sole of your shoes comes off or crumbles, you do not have to throw it away immediately. woody® offers the option of equipping most shoes with new soles. So you can continue to use your favorite shoes and protect the environment at the same time.

For further information contact us at woody@woody.co.at

Du hast noch fragen?

Dann schreib uns einfach und wir antworten dir so schnell als möglich.